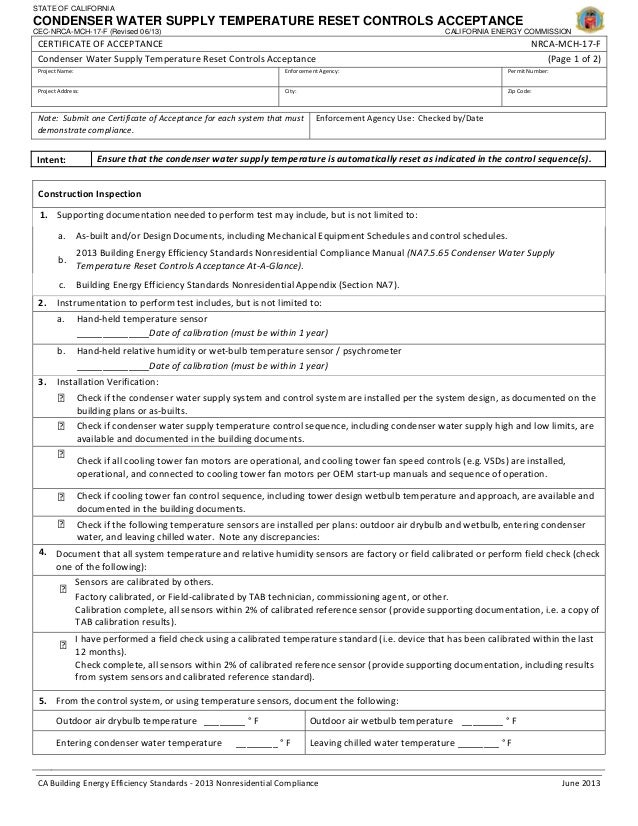

Condenser Water Reset Sequence Of Operation

This is because lowering pump speed with the differential pressure reset strategy sequence 33 competes with chwst reset but dp reset will save more energy than resetting the chilled water temperature up per ton of cooling.

Condenser water reset sequence of operation. Colder tower water isn t free. This sequence is intended to provide the design professional with a basic guideline of minimum requirements for a typical steam to hot water convertor sysyem dual exchangers. The chilled water temperature will be reset upward only when the secondary pumps speeds are at their minimum as described in sequence 33. Sequence of operation guideline.

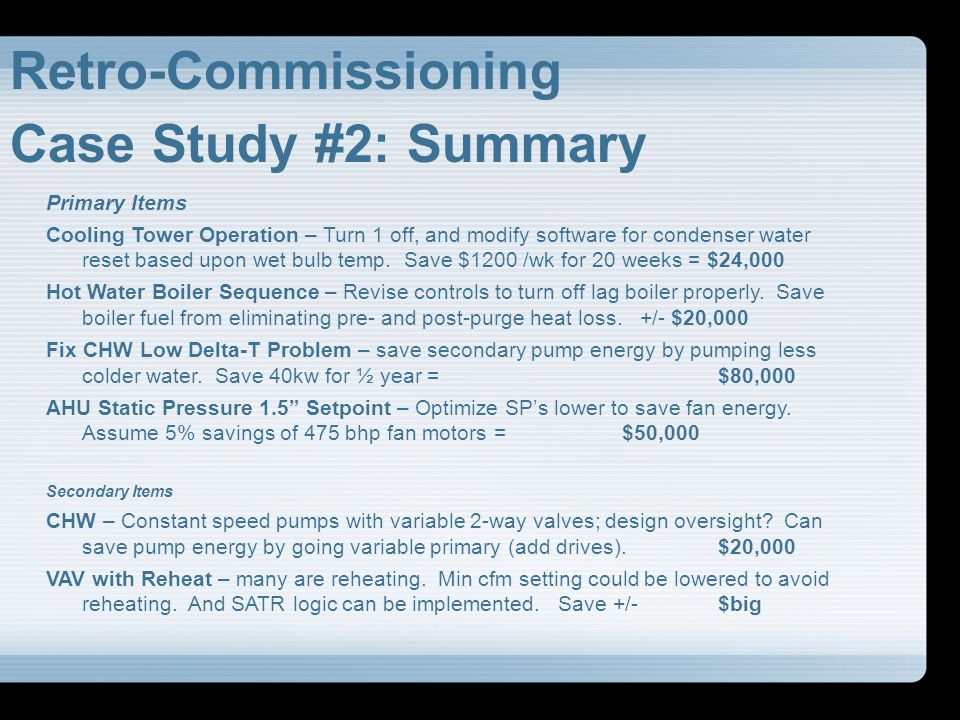

It requires additional fan energy. 6 sequence for chilled water pumping systems 6 1. Chilled water systems much attention is given to the chilled water side often ignoring significant opportunities to retrofit the condenser water system. Through examples this engineers newsletter focuses on energy saving opportunities specific to condenser pump cooling tower fan use and system sequence of operation and control.

Hot water supply temperature based on outside air or hw valve position condenser water temperature based on ambient wet bulb many others hhw oat reset 120 130 140 150 160 170 180 190 200 20 40 60 80 oat f hhw setpoint f. 7 sequence for static pressure reset 7 1. For example your chiller has a full load efficiency rating of 0 68 kw ton it is possible with part load operation to achieve an efficiency of 0 34 kw ton and even lower when this strategy. A sequence that identifies the failure of this component can reset the supply fan to some fixed speed that keeps the system in operation and provides at least partial capacity until the maintenance team can properly address the problem.

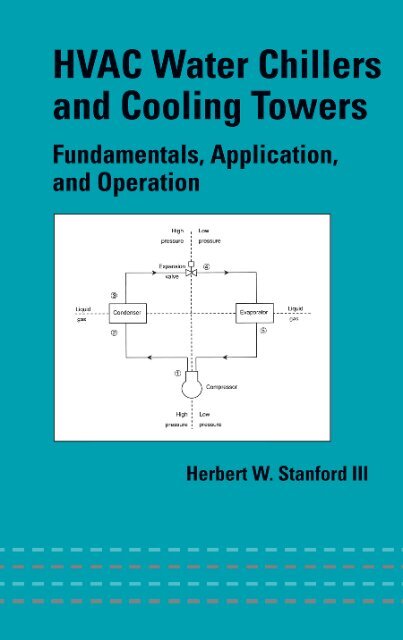

While chiller efficiency generally improves as the condenser water temperature decreases the lowest tower water temperature may not be the most economical system choice. Steam hot water heat exchanger dual. Chilled water pumping systems shall be start stopped by a campus chilled water differential sensor and shall be modulated by a differential pressure sensor installed across a cooling coil indicated on the blueprints. Consequently the optimum condenser water.

This device then opens the tower cell supply valves in sequence to each cell first maximizing the use of fill material surface area in convective heat transfer prior to engaging the fans in sequence. Condenser water temperature at these off design conditions. Condenser water temperature reset cw reset for short is an optimization strategy for chillers that will improve the chiller s efficiency by more than 50.