Condenser Water Pump Cavitation

Excessive vibration leading to premature seal and bearing failure.

Condenser water pump cavitation. The imploding or collapsing of these bubbles trigger intense shockwaves inside the pump causing significant damage to the impeller and or the pump housing. How can we help you. Having said all of that sometimes a crackling or banging sound on the suction side of a pump is cavitation which is related to the velocity at the inlet of the pump and occurs because of the reduction in static pressure associated with the increase in velocity that occurs as the water accelerates into the eye of the impeller. Improper application of tower bypass controls.

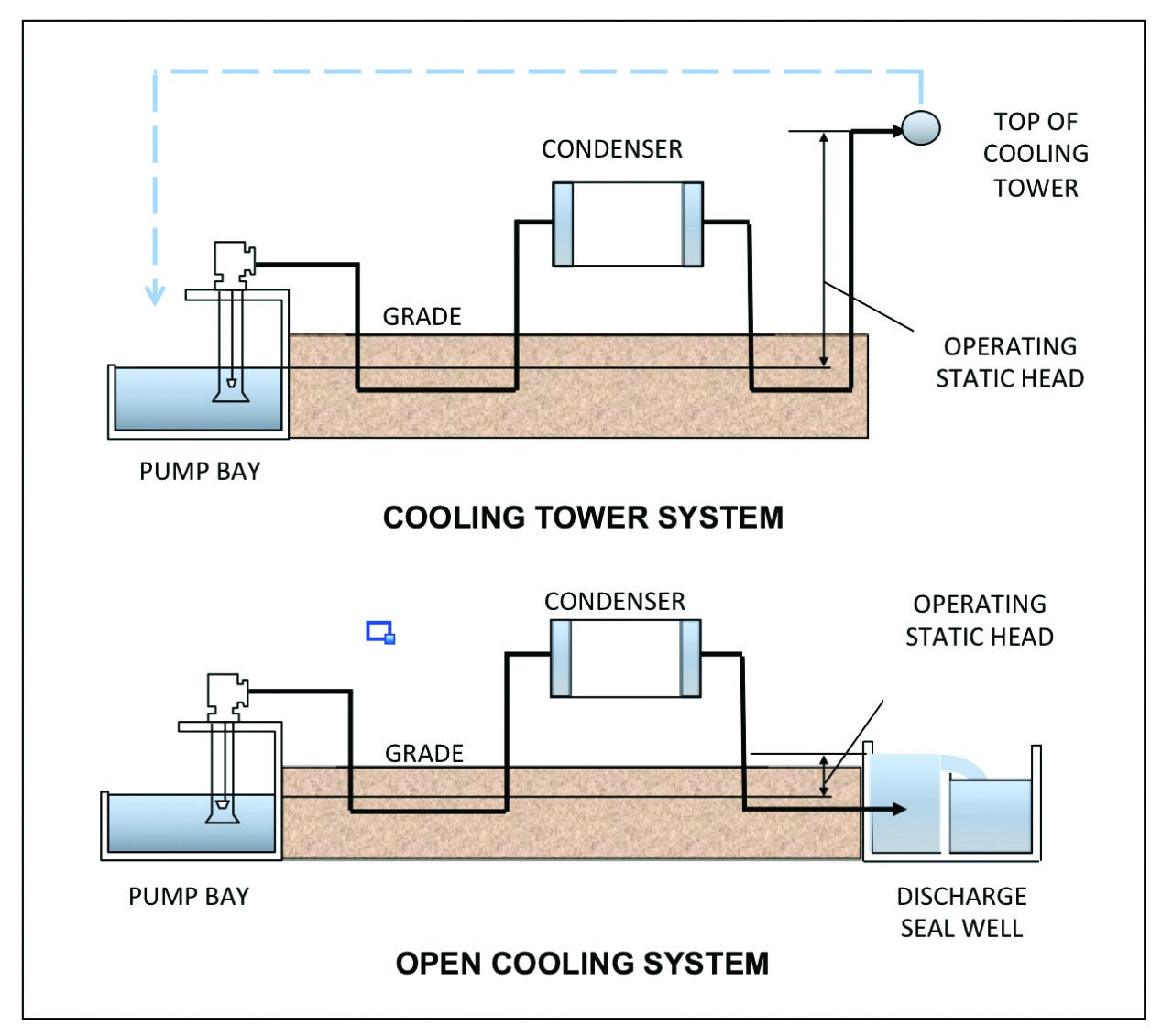

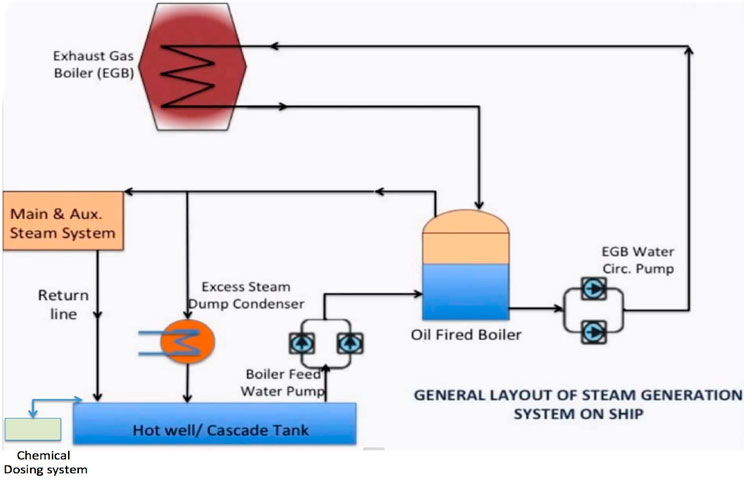

Another potential problem depending on the temperature of the water is the possibility of cavitation should the pressure drop be so great that some amount of water flashes to steam upon entering the pump. Air in pump suction. Unstable pump operational points as caused by. Incorrect pump head estimation.

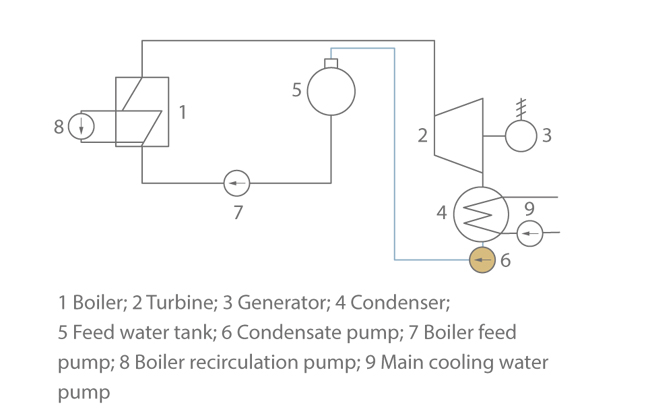

Circulating water cw pumps used for condenser cooling are normally the largest pumps at a power station commonly delivering flows of 150 000 gallons per minute or higher. Failure of pump housing. Cavitation is caused by the presence of gas bubbles under high pressure being suddenly subjected to a low pressure. The two pumps working together prevent cavitation the formation of bubbles caused when the pressure in a flowing liquid is less that its vapor pressure.

Pump cavitation and loss of pumping ability as caused by inadequate pump suction pressure. Discharge cavitation occurs when the pump s discharge pressure is too high. Hydronic pump cavitation hvac water problems cavitation is often occurring when one hears popping and crackling noises passing through the pump. The cause of cavitation in pumps is usually due to insufficient npsh net positive suction head energy on the suction side of the pump.

Higher than necessary power. This causes the bubbles to burst implode and release energy to the metal surface which causes the fracture of small minute pieces of metal from the base casting. As caused by tower pan vortex pan drain down or faulty bypass. Under these conditions it s difficult for the fluid to flow out of the pump.

These abnormal noises are the result of these tiny bubbles collapsing. Simply defined cavitation is the formation of bubbles or cavities in liquid developed in areas of relatively low pressure around an impeller. Npsh is the energy required to push the liquid into the pump. Here are some best practices for suction piping.

Instead it continues moving at high velocities inside the working chamber forming bubbles in the process. Common causes of discharge cavitation include.