Condenser Water Loop System

The onicon turbine flow meter is a great choice for measuring water flow rates in closed loop systems.

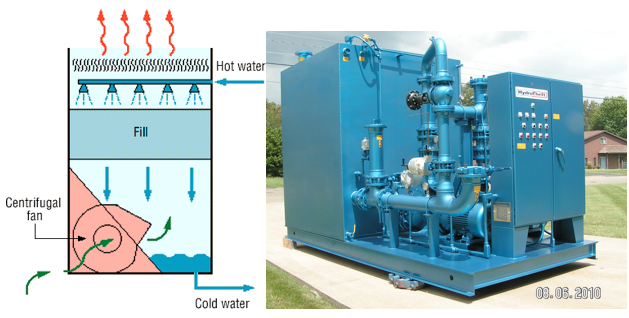

Condenser water loop system. But despite their simplicity cooling towers play a crucial role in operational efficiency of the entire chilled water system. Efficient operation of individual devices as well as the whole condenser water loop has been intensively studied in recent years. The closed water loop provides condenser water to the interior zone cooling units picking up the heat normally rejected to a cooling tower and transferring it as the heat source evaporator load for the perimeter zone heat pumps. Secondary condenser water loops are used to transfer heat away from chillers and into cooling tower water thereby providing an intermediary step between the chiller and cooling tower water.

This loop also requires a condenser water pump to circulate the cw through the piping between the chiller and the cooling tower or heat rejection device radiator or closed circuit cooler. The condenser loop is constructed by using a plantloop object. Lack of tower treatment with consequent fouling of the condenser. The chilled water circulates through a chilled water loop and through coils located in air handlers.

Since the condenser water loop is a main function block of hvac systems its energy consumption contributes significantly to the overall operating cost. Onicon offers the technologies required to accurately and reliably measure this challenging application. For water cooled chillers a condenser water loop is necessary and always operates when the chiller is energized to operate. It s best to begin by thinking about the chilled water system in 3 parts or stages.

The only pump head. It uses a cooling tower modeled by using a coolingtower singlespeed object class and a constant speed pump modeled by using a pump constantspeed to supply cooling water to the electric chiller modeled by using a chiller electric object. The chiller basically removes heat from the water. It is used as a refrigerant to remove heat from the building.

See figure 1 each of these stages overlaps via some form of heat transfer ultimately taking the heat from the building and releasing it to the atmosphere using sequential media. Removing contact between the cooling tower water and chiller allows an added layer of protection for the chiller as cooling tower water chemistry is less. The block diagram of condenser water loop. Open tower system pump head requirements.

Chilled water systems include other hvac equipment designed to exchange heat such as computer room air conditioners. 1 the condenser water side 2 the evaporator side and 3 the load side. The most important measurement points required to operate a condenser water system at peak performance are the water flow rates and temperatures.