Condenser Water Pump Vfd Control

Water systems the major water systems in hvac system include chilled water system condenser water system and hot water system.

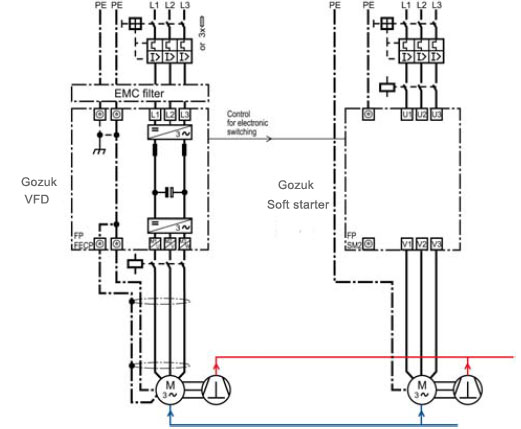

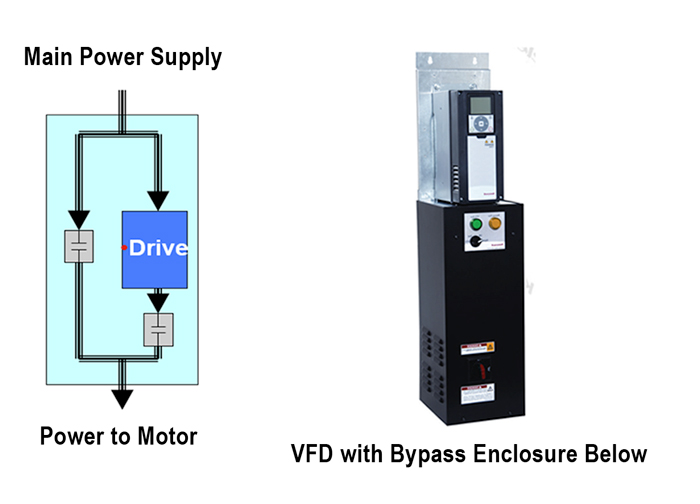

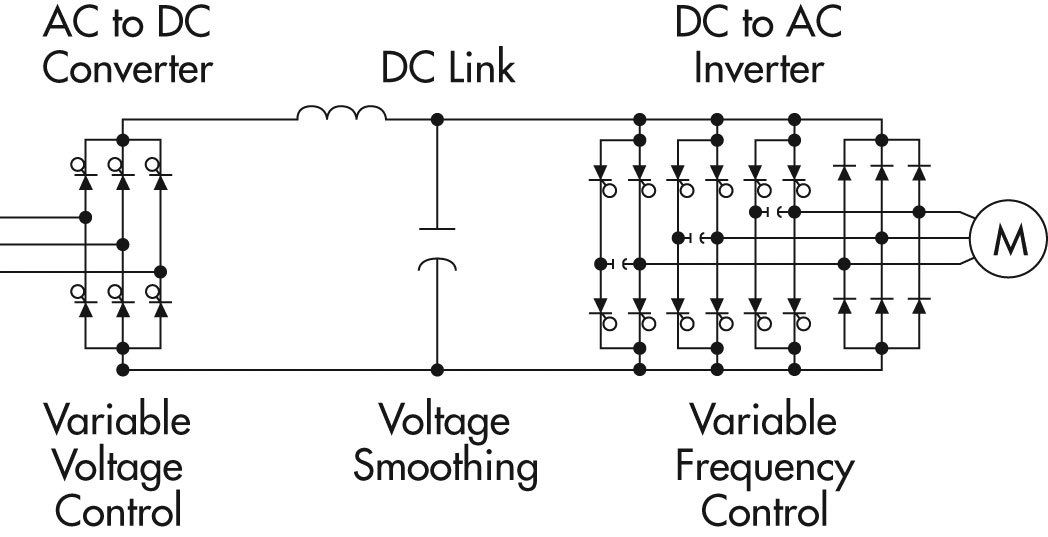

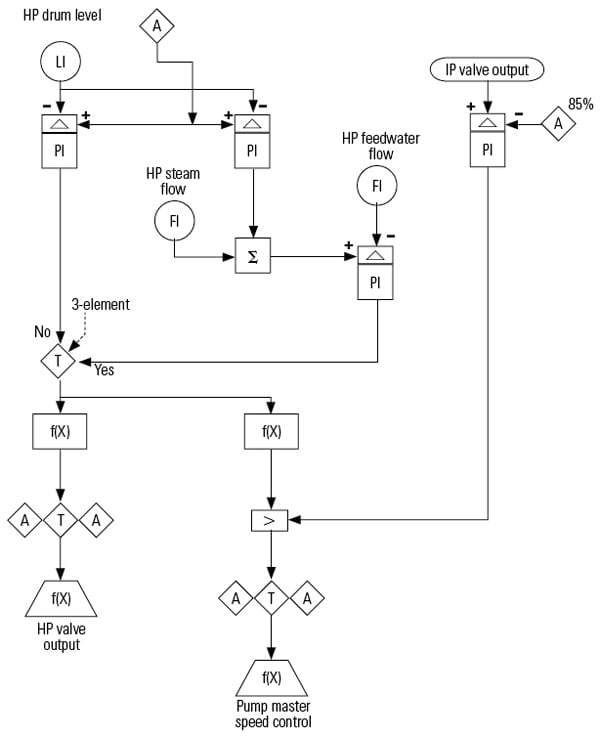

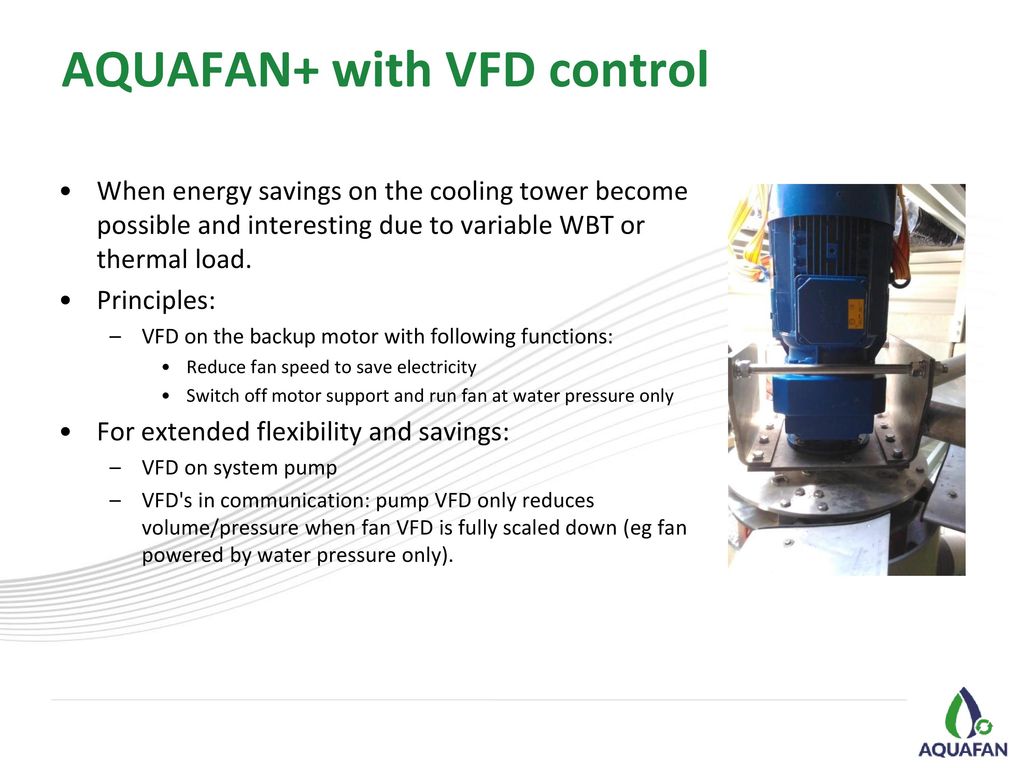

Condenser water pump vfd control. Typically the best course of action is to establish a condenser water minimum flow for each pump and vary the condenser water flow based on chiller loading. When variable condenser water flow and variable speed cooling tower fans are implemented on the same system care must be taken in the development of control strategies. See attached article for some explanation of vfd effect on the system hydraulic. The vfd is a device that controls the speed and power drawn by various electrical components in a mechanical system.

The control technology of vfd is closely related to characteristics of pumps. Each system has dedicated pumps circulating water through a closed or an open loop. To optimize the system we need to consider a few critical points including overall cooling capacity vfd cycling and size and start up sequence. Vfds can be installed on these systems which could reduce the pump energy consumption at partial load conditions.

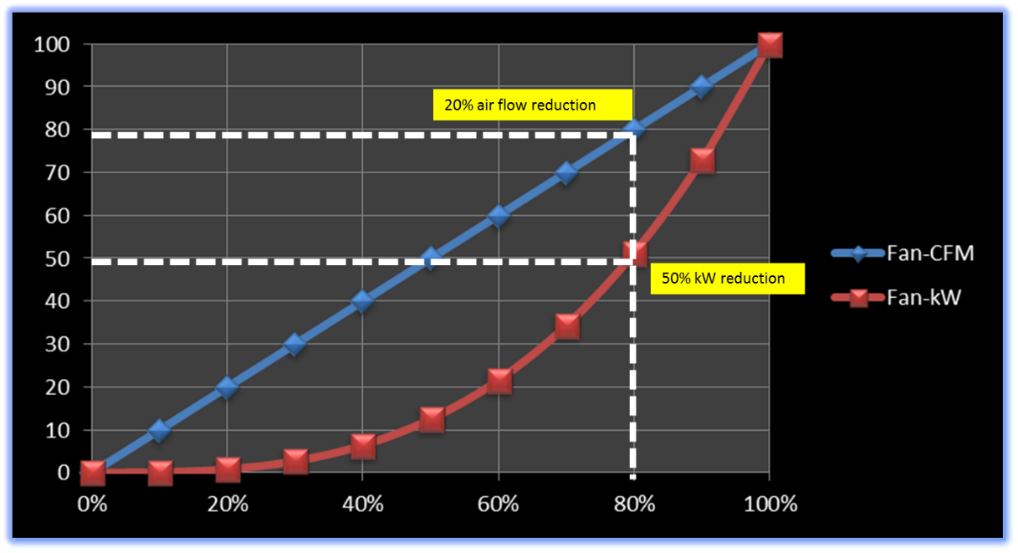

In the case of a system used to maintain water pressure in a building the vfd automatically increases the motor s speed and the pump s output as the feedback signal shows a drop in pressure. In variable flow pumping strategies a two way valve modulates condenser water flow in response to refrigerant head pressure. While lowering the flow rate through the condenser in creases chiller power consumption slightly it allows the tower to operate more efficiently and significantly reduces condenser pumping power. As demand drops the control valve starts to close the closure of the control valve causes system flow to drop as the control valve closes the dp sensor recognizes an increased pressure differential across the coil and control valve.

In pump control applications the vfd s built in pid feature is used to continuously monitor a feedback signal to maintain an output set point by adjusting motor pump speed. Chiller s cooling tower and the pumps that circulate evaporator and condenser water. Based on the mathematical a model of pumps with or without variable frequency drives the paper discusses some issues in detail such as variable frequency drives configuration flow rate regulation and overload. Differential pressure transducers control the pump speed.

You typically use vfd to maintain constant pressure.